Fibre Drum Plant

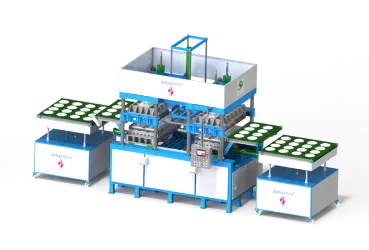

FIBRE DRUM PRODUCTION LINE

Activity

To manufacture cylindrical Fibre drums using kraft board

Type of Products

Cylindrical Fibre Drums for packaging of bulk drugs, chemicals, engineering components, automobile accessories, etc.

Size

Minimum Inner dia : 150 mm

Maximum Inner dia : 460 mm

Maximum wall thickness : 3 mm

Maximum height of the can / drum : 900 mm

Output @ 100% Efficiency

400 to 600 drums per shift depending upon the sizes

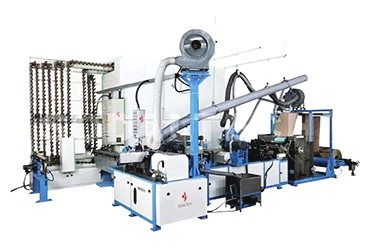

Plant & machinery

Spiral Paper tube winder (Drum body maker) – 1 No.

16 Ply Reel stand and Glue tank – 1 No.

On-Line Fine cutter – 1 No.

Ring Fixing machine – 1 No.

Bottom Plywood fixing machine – 1 No.

Plywood Disc cutting machine – 1 No.

Land & Building (Approx)

500 Sq. mtrs

Power Required (Approx) including Air Compressor

36 KW

Operators Required

5 Persons per shift

Raw Material Requirement

Recycled kraft paper reels, synthetic resin adhesive or starch based dextrine

Technical Know- How, In-Plant, Training And Marketing Guidance

As SODALTECH has their own paper products division, an extensive training and guidance are provided along with latest technical know-how at reasonable extra cost.

Equipments out of Our Scope of Supply

1.Slitter Rewinder

2.Air Compressor

3.Q.C.Equipment

NOTE

The production capacity indicated above is only approximate and does not include any tool changing times or similar. The production efficiency and the output figures may vary in practical operation according to sizes of the products, operator efficiency, weather etc.

Corporate Video

Our Machinery

Previous

Next