Edge Protector Plant

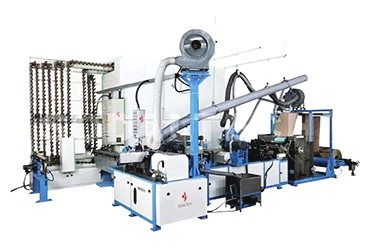

EDGE PROTECTOR PRODUCTION LINE

Activity

Type Of Products

Sizes Made (Angle Boards)

Output

Plant & machinery

SODALTECH AUTOMATIC EDGE PROTECTOR MAKING PLANT consists of mainly :

Reel stand & glue tank

Forming machine

On-line cutting machine

Recutting machine

Land & Building (Approx).

Power Required (Approx).

Labour Required

Raw Material Requirement

a) Recycled kraft board or core board reels

b) Starch based & synthetic based glue

Technical Know- How, In-Plant, Training And Marketing Guidance

NOTE

Activity

Size

Minimum Inner dia of the can : 25mm

Maximum Inner dia of the can : 127mm

Maximum height of the can : 525mm

Maximum Wall thickness : 5mm

Output @ 100% Efficiency

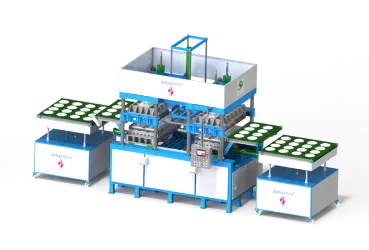

Plant & machinery

1. CCW (E) Can Body Maker – 1 No.

2. 10-Ply Reel Unwinding Stand & Glue tank – 1 No.

3. Outer layer unwinding stand – 1 No.

4. HLM 550 Convolute Labelling machine – 1 No.

5. ETR 2000 Paper tube Recutter – 1 No.

6. Heat Sealing equipment

Factory Shed

Power Required (Approx)

Labour Required

Raw Material Requirement

Technical Know- How, In-Plant, Training And Marketing Guidance

As SODALTECH has their own paper products division, an extensive training and guidance are provided along with latest technical know-how at reasonable extra cost.

Raw Material Requirement

Slitter Rewinder

Can Seaming machine

Material handling & Q.C.Equipments

Air Compressor

NOTE

Corporate Video

Our Machinery