Paper Cone Plant

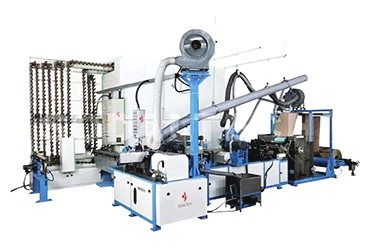

FULLY AUTOMATIC PAPER CONE PLANT WITH ONLINE DRIER

Activity

Output @ 100% Efficiency

Plant & machinery

Fully automatic Paper cone Plant model APC 50 consists of mainly the following with a capacity of upto 50 cones / minute (approx) :

a. Automatic cone making machine with standard accessories ACW 50

b. On-Line Drier CD 50 K (E)

c. Automatic Cone Finishing machine ACF 50 (TI)

d. Any one standard size (conicity) cone manufacturing attachment (tool set)

400 Sq. mtrs

Power Required

Labour Required

1 Operator + 2 helpers per shift

Raw Material Requirement

Technical Know- How, In-Plant, Training And Marketing Guidance

NOTE

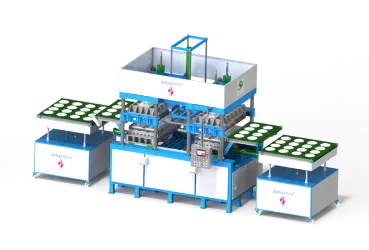

AUTOMATIC PAPER CONE MAKING MACHINERY – DCW SERIES

OUTPUT : 40,000 CONES / DAY @ 100% EFFICIENCY

Activity

SODALTECH Automatic Paper Cone Plant consisting of :

1. Automatic Paper Cone Winding machine Model DCW 500 – 1 No.

2. On-Line Conveyorised Paper Cone Drier Model 50 K – 1 No.

3. Automatic Paper Cone Finishing Machine (Multi-process) – 1 No.

NOTE

PAPER CONE PLANT – (REEL MODEL)

OUTPUT : UPTO 40,000 CONES / DAY @ 100% EFFICIENCY

Activity

Output @ 100% Efficiency

Upto 40,000 cones per day (24 hours operation) @ 100% efficiency

Paper Cone Plant (Reel Model) consists of :

1. Paper cone Pattern Forming machine (Output 100 patterns per minute) – 1 No.

2. Glueing machine – 1 No.

3. Paper Cone winders – 3 Nos.

4. Automatic Paper cone finishing machine – 1 No.

NOTE

Corporate Video

Our Machinery